Unlocking the Mysteries of Mold Transfers

For a variety of reasons, you may be reconsidering your current injection molding source. Your needs may have changed, external constraints may have arisen or you may simply be dissatisfied with your service. If you are looking to reallocate your business, you might want to consider a mold transfer.

What is a mold transfer?

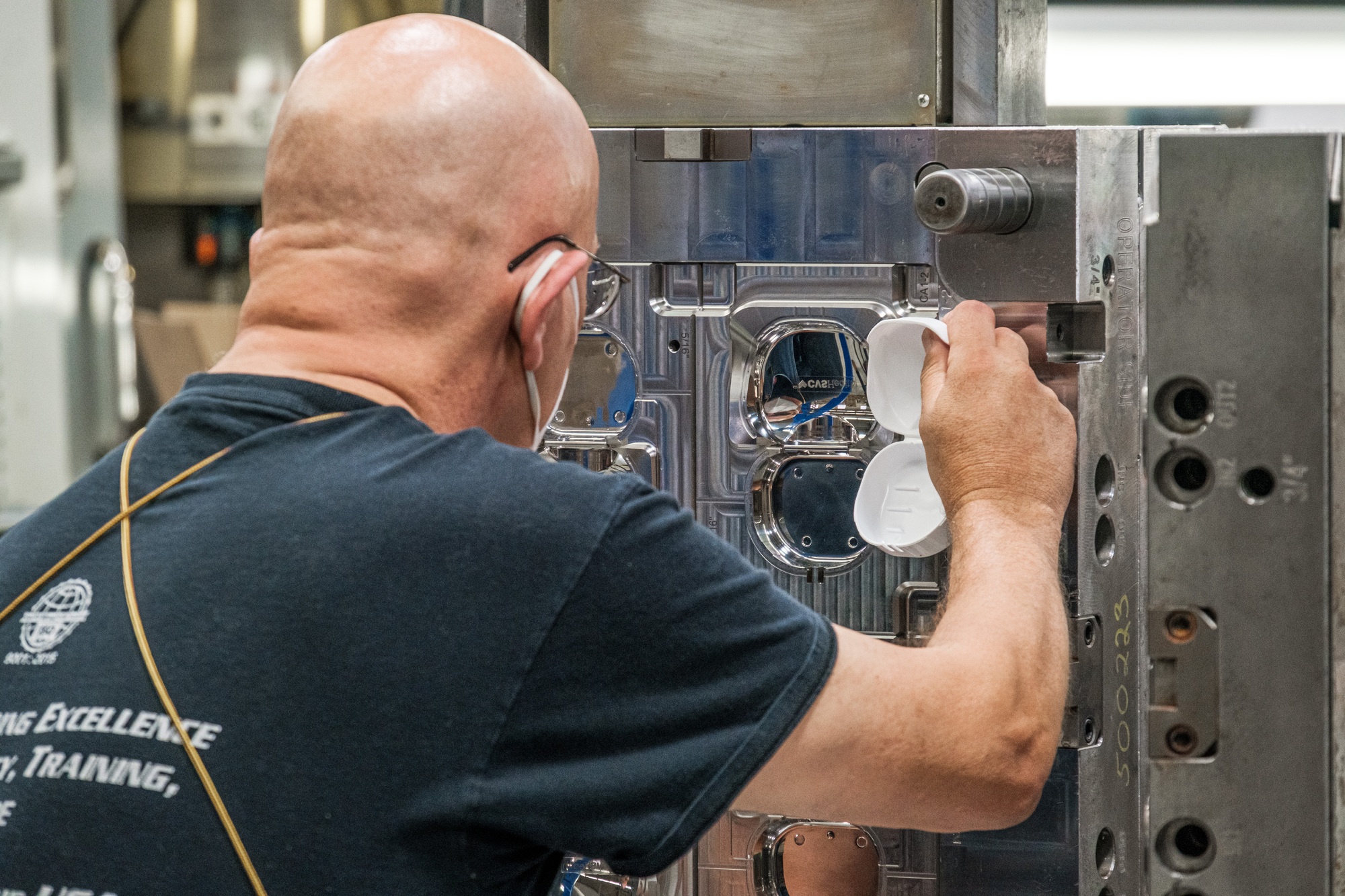

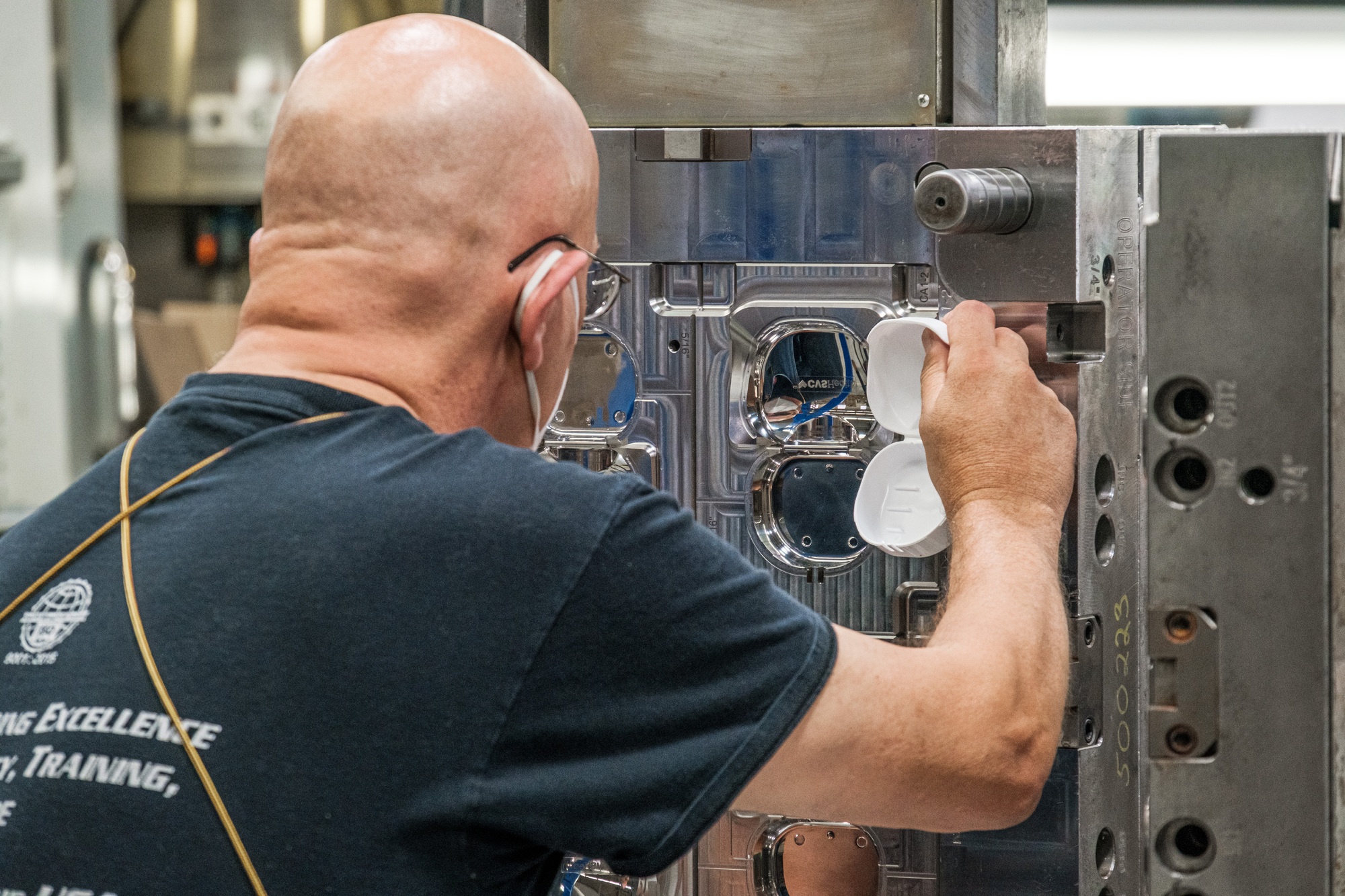

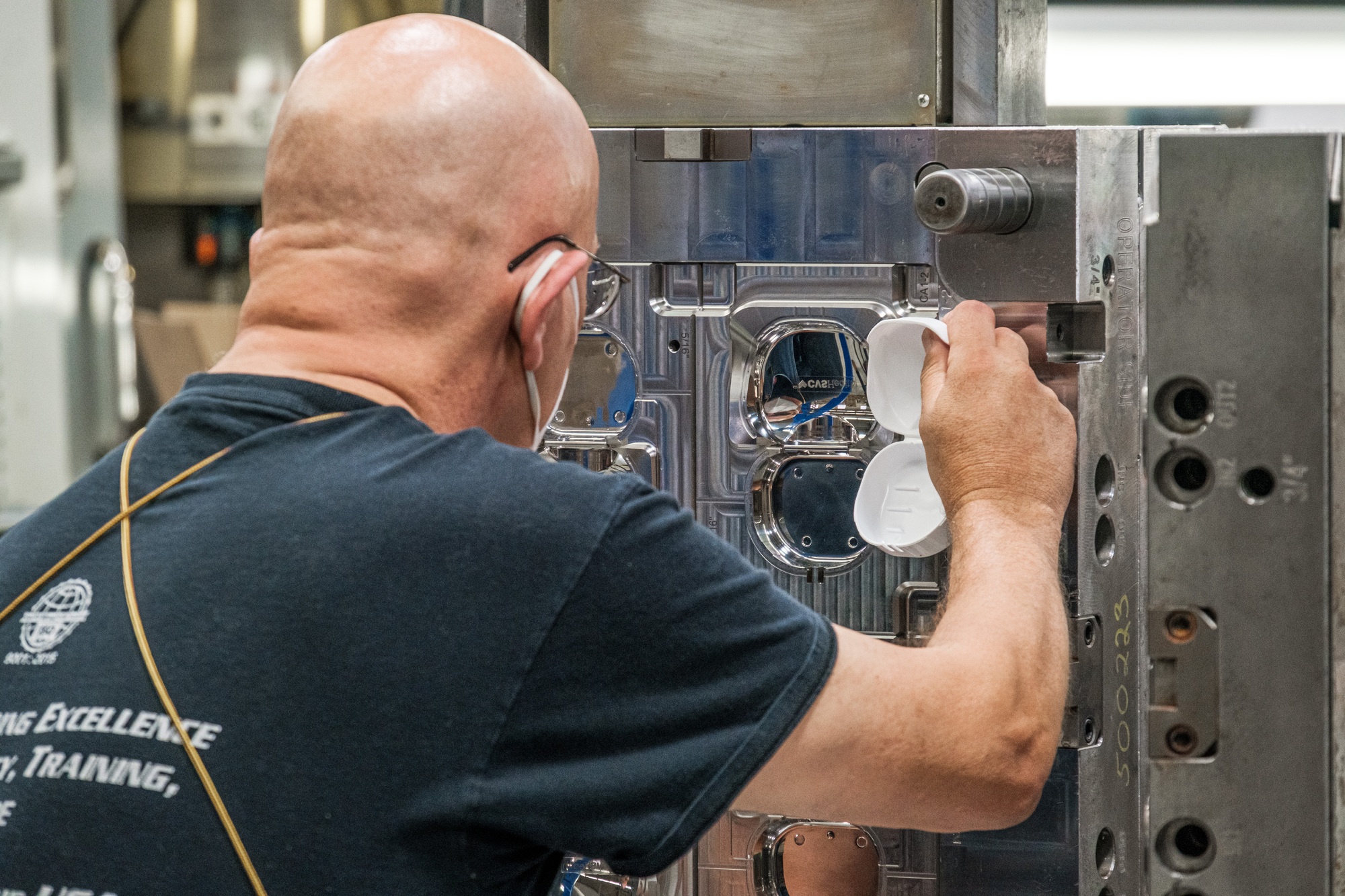

Put simply, it is moving your mold from one injection molder to another. A mold transfer involves a transition process, whereby your customer-owned mold is retrieved from your current molder and shipped to the new molder. Once the mold arrives at its new home, the new injection molder will inspect your mold’s current condition. This is done to check for any normal tool wear, possible tool damage and to ensure a seamless fit in the new facility. Though pre-transition qualification will be done to ensure your mold will perform at your new molder, there could be small alterations required once on site.

Why should I consider a mold transfer?

There are numerous reasons why your company might be considering the idea of relocating your mold(s) from its current location. Your current injection molder may no longer be an ideal partner. You may be looking for more tailored service, your overall quality expectations are not being met, or you might be in search of a lower component price as a way to reduce supply costs. Your job requirements may have exceeded your current molder’s capabilities, or your current molder may be transitioning their business. Your current molder may have been acquired by a new stakeholder with completely different business philosophies and priorities. If you have been partnering with an international molder, tariffs, freight delays, inferior quality or other trade risks may threaten to disrupt your supply chain.

If you are satisfied with your current molder, there is no need to consider a mold transfer. Take a look at our past blog “Reasons to Transfer Molds & How to Navigate the Process” for a more in-depth discussion on why a mold transfer might be right for you.

What should I look for when considering a new injection molder for a mold transfer?

It is critical to partner with an experienced, full-service injection molder who has an established process to inspect, evaluate and test transferred molds supported by extensive Engineering, Processing and Quality systems. If your mold was not properly cared for at its previous facility, wear or damage may lead to production downtime or molded part defects. If you or your previous molder is unable to provide complete information about the mold’s design and history, improper set-up and handling may lead to premature tool wear or process delays.

An injection molder experienced in mold transfers will have a point-by-point mold review checklist to evaluate your mold before entering production and a Tool Room staff able to address pre-existing wear or damage, make corrections and perform molding tests. Your new molder should also be able to make recommendations to optimize your mold’s performance and lifespan, though specific suggestions may not be possible until the mold arrives on site.

You should be sure to evaluate the capabilities of a potential supplier: are they able to service your size and type of mold? Have they worked within your industry before? Are they experienced with the variety of resin required for your part? While these questions may seem like common sense considerations, inexperienced molders may not know to ask or are not sufficiently forthright. Be sure to ask about your potential supplier’s press capacities; both clamp tonnage and shot size; the availability of core pull; hot runner controllers; and machine orientations; as well as sample case studies from your industry—such as these from Stelray.

Perhaps most important is evaluating your mold transfer partner’s Quality Management System (QMS). Be sure you have complete comfort with their QMS: from First Article Inspection, to lot control of raw materials and Production to Process Validation, if need be. Ask about their quality certifications, such as ISO 9001:2015, to be sure they are equipped to meet your expectations. Your specific industry may require additional standards, such as FDA Registration. Take a look at Stelray’s Quality Assurance mission to see how we define our standards for precision.

How long does a mold transfer typically take?

Every injection mold is unique and the timeline to production startup will vary accordingly. Most critical to the shortest possible turnaround is a molding partner with an experienced, in-house tool room. Seasoned tool builders will know how to efficiently assess your mold and its requirements to ensure quick, high-quality startup with proper care, maintenance, and restoration if necessary.

Make sure to understand your mold transfer partner’s moldmaking and tool maintenance capabilities. If their resources are not in-house, not only will your startup time lengthen but delays in production will also incur added downtime. A molder with an in-house tool room like Stelray will be able to ensure the quickest startup turnaround and a minimum of tool downtime in production.

This is all a little intimidating!

Understandably so. A mold transfer should not be taken lightly—this is a big change for you and your business, but it is often crucial to unlocking the potential of a program. The right partner will be by your side every step of the way, communicating transparently and providing frequent timeline updates. The right partner will make this process simple and easy, asking the right questions and leveraging on their previous experience to ensure a smooth transition and seamless fit.

And remember: once the mold transfer process is complete, that is only the very beginning of a new relationship. The right partner will continuously maintain your mold to ensure its maximum lifespan and output quality throughout production. To minimize the intimidation factor, look for a partner with the capabilities you need and the service you deserve.

With decades of experience and dozens of molds transferred successfully, Stelray is not only your preferred destination for precision injection molding but also your best resource for mold transfer consultation. If you are considering a mold transfer for your injection molded part or your entire injection molding program, please give Stelray a call.