Reasons to Transfer Molds & How to Navigate the Process

Several factors can put companies on the hunt for new manufacturing partners. However, the cost and associated fear of having to fabricate a new mold and the associated downtime can sideline that desire for change—even when switching suppliers can deliver big savings.

Stelray has the solution.

Unlike many in the industry, our expert staff of Engineers, Mold Makers, and Technicians have the know-how and the capabilities to accept molds produced by other molding facilities and bring them in-house and operating seamlessly at Stelray.

Here are the 5 most common reasons companies transfer their existing molds to us. If you see yourself here, give us a call. Even if you don’t, we’d still love to hear from you.

Quality standards erode or aren't being met

The importance of meeting critical dimensional tolerance requirements for high-precision applications in industries like healthcare, bioscience and electronics cannot be overstated. Given these types of challenges in the absence of comprehensive mold maintenance, quality can erode to the point where standards are no longer met.

Every mold transfer project at Stelray begins with our Program Review process to ensure that your needs are met from beginning to end. As part of our services, we offer:

- Complete tool review and review of documentation

- Quality Assurance and inspection methods overview

- Inspection fixtures custom-engineered and built in-house as required

- Establish a preventative maintenance schedule for your tooling

- Raw material and molding process review

- Packaging review

Our backend mold services consistently result in the highest-quality custom plastic injection molded parts and equipment, as demonstrated by our outstanding supplier record working with an array of top U.S. and international brands.

We’re certified and conform to the following standards:

- ISO 9001:2015

- FDA Registered Medical Device Manufacturer

- FDA Current Good Manufacturing Practice (CGMP)

- FDA 21 CFR 820

- International Organization for Standardization

- UL-Underwriters Laboratories

- American National Standards Institute (ANSI)

- American Society of Mechanical Engineers (ASME)

- American Society for Testing & Materials (ASTM)

- Conformité Européenne (CE)

When your needs grow beyond production capacities

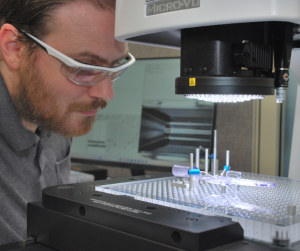

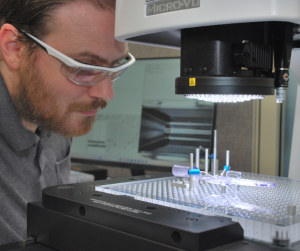

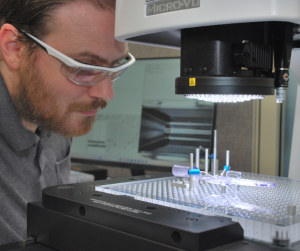

Our 42,000-square-foot facility and 3-shift molding operations are fully equipped and always ready, whether for prototype development of one part or production requirements of 10 million units produced on industry-leading molding equipment using high-cavitation hot-runner molds. Stelray’s new Micro-Vu measuring system and 618-ton molding machines supplement our current capabilities and ensure Stelray is keeping up with the latest technology and has the ability to manufacture and inspect a broad range of products.

To ensure you stay on schedule and budget, we offer:

- Quick turnaround, speed to market & just-in-time deliveries

- Kanban stocking programs

- Blanket orders for volume discounts

- Lights-out manufacturing

- 24-hour staff scheduling

You require additional specialized post-mold services not otherwise available

At Stelray, we offer a range of post-molding value-added services for our customers who require more than just a molded part.

Pad-printing, hot stamping, painting, plating and shielding services are available for decorating and coating requirements. In addition, ultrasonic welding and heat-staking resources are available to accommodate molded joining needs. If your program requires packaging or assembly, we offer an array of options from bagging and boxing to complete fulfillment programs.

Our expert team of engineers will work to bring your pre-existing mold online quickly to minimize production impacts and deliver high-quality products at the best possible price.

Production costs rise beyond what's reasonable

Production costs can change over time, given manufacturers aren’t any more immune to the vagaries of supply chain than anyone else. Stelray’s longtime relationships with suppliers, however, helps us to better weather raw material fluctuations and disruptions—mitigating impacts on customers.

Beyond that, our creative approach to streamlined manufacturing and problem-solving allows us to build in cost-savings without forfeiting excellence. We’ll work with you to maintain the same high-quality complex components and assemblies at the best possible price over time.

Existing supplier ceases operations or encounters operational difficulties

Businesses might cease operations for two reasons: closure due to insolvency or providing customers with inadequate service delivery.

Stelray has been in business for 60 years and maintains long-term relationships with top U.S. and international brands like ITT, Panasonic, Hill-Rom, Hubbell, Sub-Zero and Welch Allyn because we consistently deliver expert high-quality service at a fair price.

Operating with integrity and providing a first-class customer experience is the foundation upon which we’ve grown into an industry-leading plastic injection molding manufacturer. Our commitment to those values and an unwavering commitment to customer service is baked into our business model and will not change.

About Stelray:

Stelray Plastic Products offers complete custom injection mold-making and mold maintenance services, which includes accepting existing mold transfers—all managed by our expert engineering team. Our staff is committed to achieving optimum tooling performance and cost-effective savings. As part of our service, we offer in-house design and long-term mold service maintenance for your company’s assets, as well as enhancements for new product needs.

To learn more about our injection mold-making services, including transferring existing molds, get in touch. Our established mold transfer program ensures the process is simple and efficient to save you time and money.