Reference Tables

Density of Plastic, Shrinkage, Draft Angle, SPI Mold Class & Conversion Reference Charts

| Plastic Shrinkage Values | |

| Material | Shrink in/in |

| ABS High Impact | 0.005 – 0.007 |

| ABS Heat Resistant | 0.004 – 0.005 |

| ABS Medium Impact | 0.005 |

| Acetal | 0.020 – 0.035 |

| Acrylic General Purpose | 0.002 – 0.009 |

| Acrylic Heat Resistant | 0.003 – 0.010 |

| Acrylic High Impact | 0.004 – 0.008 |

| Ethylene Vinyl Acetate | 0.010 – 0.030 |

| Ionomer | 0.003 – 0.020 |

| Nylon 6/6 | 0.010 – 0.025 |

| Nylon 6/6 | 0.007 – 0.015 |

| Nylon 6/10 | 0.010 – 0.025 |

| Nylon 11 | 0.010 – 0.025 |

| Nylon 12 | 0.008 – 0.020 |

| Nylon Glass Filled | 0.005 – 0.010 |

| Polybutylene | 0.020 (molded) |

| Polybutylene | 0.040 (aged) |

| Polycarbonate | 0.005 – 0.007 |

| PET (Amorphous, petg, pctg) | 0.003 – 0.005 |

| Polyester .025 – .050 THICK | 0.006 – 0.012 |

| Polyester .050 – .100 THICK | 0.012 – 0.017 |

| Polyster .100 – .180 THICK | 0.016 – 0.022 |

| Polyester PBT | 0.010 – 0.020 |

| Polyester PET 30% GF | 0.001 – 0.002 |

| Polyester PBT 30% GF | 0.003 – 0.005 |

| POLYETHERIMIDE | 0.005 – 0.007 |

| Polyethylene Low Density | 0.015 – 0.035 |

| Polyethylene High Density | 0.015 – 0.030 |

| PPO/Styrene CO (NORYL) | 0.005 – 0.007 |

| Polypropylene | 0.010 – 0.030 |

| PPO/Styrene G.P. | 0.002 – 0.008 |

| PPO/Styrene Heat Resistant | 0.002 – 0.008 |

| PPO/Styrene Impact Mod | 0.003 – 0.006 |

| Polysulfone | 0.008 |

| Polyurethane | 0.010 – 0.020 |

| PVC Rigid | 0.002 – 0.004 |

| PVC Semi-Rigid | 0.005 – 0.025 |

| PVC Flexible | 0.015 – 0.030 |

| SAN | 0.002 – 0.006 |

| Density of Plastic Values – Selected Resins | ||

| Material |

70°F DENSITY gr/cc |

MELT DENSITY gr/cc |

| Density of ABS (Injection Grade) | 1.05 | 0.97 |

| ABS 30% GR | 1.28 | |

| ABS, FR | 1.19 | |

| Acetal | 1.42 | 1.17 |

| Acetal 20% GF | 1.55 | |

| Acrylic (General Purpose) | 1.16 | 1.04 |

| Cellulose Acetate | 1.26 | 1.13 |

| Cellulose Butyrate | 1.20 | 1.07 |

| Cellulose Propionate | 1.22 | 1.10 |

| Ethylene Vinyl Acetate | 0.95 | |

| Ionomer | 0.95 | 0.73 |

| Nylon 6/6 Density | 1.14 | 0.97 |

| Nylon 6 Density | 1.13 | 0.97 |

| Nylon 6/10 Density | 1.08 | 0.97 |

| Nylon 6/12 Density | 1.07 | 0.97 |

| Nylon 11 Density | 1.04 | 0.97 |

| Nylon 12 | 1.02 | 0.97 |

| Nylon 30% GF | 1.36 | |

| Polybutylene Density | 0.92 | |

| Polycarbonate Polyester Alloy | 1.20 | |

| Density of Polycarbonate | 1.20 | 1.02 |

| Polycarbonate 30% GF | 1.42 | |

| Co-Polyester PETG | 1.27 | 1.12 |

| Co-Polyester PCTG | 1.24 | 1.08 |

| Polyester PBT | 1.34 | 1.11 |

| Polyester PBT/PET 30% GF | 1.58 | |

| Polyester PET (Bottle) | 1.40 | 1.20 |

| Polytherimide | 1.27 | |

| Polyethylene Low Density | 0.92 | 0.76 |

| Polyethylene Medium Density | 0.92-0.94 | 0.74 |

| Polyethylene High Density | 0.94-0.97 | 0.72 |

| Polythyl 30% GF HDPE | 1.18 | |

| PPO/Styrene (NORYL) | 1.07 | 0.90 |

| Polyphenylene Sulfide (Ryton, Fortron) | 1.35-1.80 | |

| Polyphenylene Sulfide/PPS 40% GF (Ryton, Fortron) | 1.65 | |

| Density of Polypropylene | 0.90 | 0.70 |

| Polypropylene 30% GF | 1.13 | |

| Polystyrene GP | 1.05 | 0.97 |

| Polystyrene Impact Mod | 1.04 | 0.96 |

| Polysulfone | 1.25 | 1.16 |

| Polyurethane | 1.20 | 1.13 |

| PVC – Rigid | 1.39 | 1.30 |

| PVC – Pipe | 1.44 | 1.32 |

| PVC – Flexible | 1.29 | 1.20 |

| SAN | 1.08 | 1.00 |

| T/P Ruber (Santoprene) | 1.08 | 1.00 |

| T/P Elastomer (Urethane) | 0.97 | 0.93 |

Common Plastic Abbreviations

| Common Abbreviations for Misc Resins | |

| Resin Generic Name | Common ABBR |

| Acrylonitrile-Butadiene-Styrene | ABS |

| Cellulose Acetate | CA |

| Cellulose Acetate Butyrate | CAB |

| Cellulose Acetate Propionate | CAP |

| Chlorinated Polyethylene | CPE |

| Chlorinated Polyvinyl Chloride | CPVC |

| Ethylene-Propylene Diene Rubber | EPDM |

| Expandable Polystyrene | EPS |

| Ethylene Vinyl Acetate | EVA |

| Fiber Reinforced Plastic | FRP |

| High Density Polyethylene | HDPE |

| High Impact Polystyrene | HIPS |

| Low Density Polyethylene | LDPE |

| Linear Low Density Polyethylene | LLDPE |

| Maleic Anhydride | MA |

| Medium Density Polyethylene | MDPE |

| Polyamide (Nylon) | PA |

| Polyacrylonitrile | PAN |

| Polybutylene | PB |

| Polybutylene Terephalicate | PBT |

| Polycarbonate | PC |

| Polyethylene | PE |

| Polyetheretherketone | PEEK |

| Polyetherimide | PEI |

| Polyetherketone | PEK |

| Polyethylene Terephalicate | PET |

| Polyethylene Terephalic Clycol | PETG |

| Polyimide | PI |

| Polymethyl Methacrylate | PMMA |

| Polyoxymethylene | POM |

| Polypropylene | PP |

| Chlorinated Polypropylene | PPC |

| Polyphenylene Oxide | PPO |

| Polyphenylene Sulfide | PPS |

| Polyphenylene Sulfone | PPSU |

| Polystyrene | PS |

| Polysulfone | PSU |

| Polyurethane | PU |

| Polyurethane | PUR |

| Polyvinyl Chloride | PVC |

| Reinforce Polybutylene Terephthalateic | RPBT |

| Reinfor Polyethylene Terephalic | RPET |

| Reaction Injection Molding | RIM |

| Styrene Acrylonitrile | SAN |

| Styrene Butadiene Rubber | SBR |

| Styrene Maleic Anhydride | SMA |

| Sheet Molding Compound | SMC |

| Thermoplastic Elastomer | TPE |

How much draft angle do you need in your plastic part?

Below are draft angles commonly used from 1/32″ to 1″ are noted in degrees in the table below.

Each block is the amount of draft with the corresponding angle and depth of the cavity.

| DEPTH | 1/2° | 1° | 2° | 3° | 4° | 5° | DEPTH |

| 1/32 | .0003 | .0005 | .001 | .0016 | .002 | .0027 | 1/32 |

| 1/16 | .0005 | .0011 | .002 | .0033 | .004 | .0055 | 1/16 |

| 3/32 | .0008 | .0017 | .003 | .0049 | .006 | .008 | 3/32 |

| 1/8 | .0011 | .0022 | .004 | .0066 | .009 | .0109 | 1/8 |

| 5/32 | .0014 | .0028 | .005 | .008 | .011 | .014 | 5/32 |

| 3/16 | .0016 | .0033 | .006 | .0098 | .013 | .016 | 3/16 |

| 7/32 | .0019 | .0039 | .008 | .011 | .015 | .019 | 7/32 |

| 1/4 | .0022 | .0043 | .009 | .013 | .018 | .022 | 1/4 |

| 9/32 | .0025 | .005 | .010 | .014 | .020 | .024 | 9/32 |

| 5/16 | .0027 | .0055 | .011 | .016 | .022 | .027 | 5/16 |

| 11/32 | .003 | .006 | .012 | .018 | .024 | .030 | 11/32 |

| 3/8 | .0032 | .0066 | .013 | .020 | .026 | .033 | 3/8 |

| 13/32 | .0035 | .007 | .014 | .021 | .028 | .035 | 13/32 |

| 7/16 | .0038 | .0077 | .015 | .023 | .031 | .038 | 7/16 |

| 15/32 | .0041 | .008 | .016 | .024 | .033 | .041 | 15/32 |

| 1/2 | .0044 | .0088 | .018 | .026 | .035 | .044 | 1/2 |

| 17/32 | .0046 | .009 | .019 | .028 | .037 | .046 | 17/32 |

| 9/16 | .0049 | .0099 | .020 | .03 | .039 | .049 | 9/16 |

| 19/32 | .0052 | .010 | .021 | .031 | .042 | .052 | 19/32 |

| 5/8 | .0055 | .011 | .022 | .033 | .044 | .055 | 5/8 |

| 21/32 | .0057 | .011 | .023 | .035 | .046 | .057 | 21/32 |

| 11/16 | .006 | .012 | .024 | .036 | .048 | .060 | 11/16 |

| 23/32 | .0063 | .013 | .025 | .038 | .050 | .063 | 23/32 |

| 3/4 | .0065 | .013 | .027 | .039 | .053 | .066 | 3/4 |

| 25/32 | .0068 | .014 | .028 | .040 | .055 | .068 | 25/32 |

| 13/16 | .0071 | .014 | .029 | .043 | .057 | .071 | 13/16 |

| 27/32 | .0074 | .015 | .030 | .045 | .059 | .074 | 27/32 |

| 7/8 | .0076 | .015 | .031 | .046 | .061 | .077 | 7/8 |

| 29/32 | .0079 | .016 | .032 | .048 | .063 | .079 | 29/32 |

| 15/16 | .0082 | .017 | .033 | .050 | .066 | .082 | 15/16 |

| 31/32 | .0085 | .017 | .034 | .051 | .068 | .084 | 31/32 |

| 1 | .0087 | .0175 | .035 | .052 | .070 | .087 | 1 |

Inches to Millimeters Conversion Chart

| Inch Fraction | Inch Decimal | mm | mm | Inch Decimal | |

| 1/32 | 0.03125 | 0.794 | 1 | 0.0394 | |

| 1/16 | 0.0625 | 1.588 | 2 | 0.0787 | |

| 3/32 | 0.09375 | 2.381 | 3 | 0.1181 | |

| 1/8 | 0.125 | 3.175 | 4 | 0.1575 | |

| 5/32 | 0.15625 | 3.969 | 5 | 0.1969 | |

| 3/16 | 0.1875 | 4.763 | 6 | 0.2362 | |

| 7/32 | 0.21875 | 5.556 | 7 | 0.2756 | |

| 1/4 | 0.25 | 6.350 | 8 | 0.3150 | |

| 9/32 | 0.28125 | 7.144 | 9 | 0.3543 | |

| 5/16 | 0.3125 | 7.938 | 10 | 0.3937 | |

| 11/32 | 0.34375 | 8.731 | 11 | 0.4331 | |

| 3/8 | 0.375 | 9.525 | 12 | 0.4724 | |

| 13/32 | 0.40625 | 10.319 | 13 | 0.5118 | |

| 7/16 | 0.4375 | 11.113 | 14 | 0.5512 | |

| 15/32 | 0.46875 | 11.906 | 15 | 0.5906 | |

| 1/2 | 0.5 | 12.700 | 16 | 0.6299 | |

| 17/32 | 0.53125 | 13.494 | 17 | 0.6693 | |

| 9/16 | 0.5625 | 14.288 | 18 | 0.7087 | |

| 19/32 | 0.59375 | 15.081 | 19 | 0.7480 | |

| 5/8 | 0.625 | 15.875 | 20 | 0.7874 | |

| 21/32 | 0.65625 | 16.669 | 21 | 0.8268 | |

| 11/16 | 0.6875 | 17.463 | 22 | 0.8661 | |

| 23/32 | 0.71875 | 18.256 | 23 | 0.9055 | |

| 3/4 | 0.75 | 19.050 | 24 | 0.9449 | |

| 25/32 | 0.78125 | 19.844 | 25 | 0.9843 | |

| 13/16 | 0.8125 | 20.638 | 26 | 1.0236 | |

| 27/32 | 0.84375 | 21.431 | 27 | 1.0630 | |

| 7/8 | 0.875 | 22.225 | 28 | 1.1024 | |

| 29/32 | 0.90625 | 23.019 | 29 | 1.1417 | |

| 15/16 | 0.9375 | 23.813 | 30 | 1.1811 | |

| 31/32 | 0.96875 | 24.606 | 31 | 1.2205 | |

| 1 | 1 | 25.400 | 32 | 1.2598 |

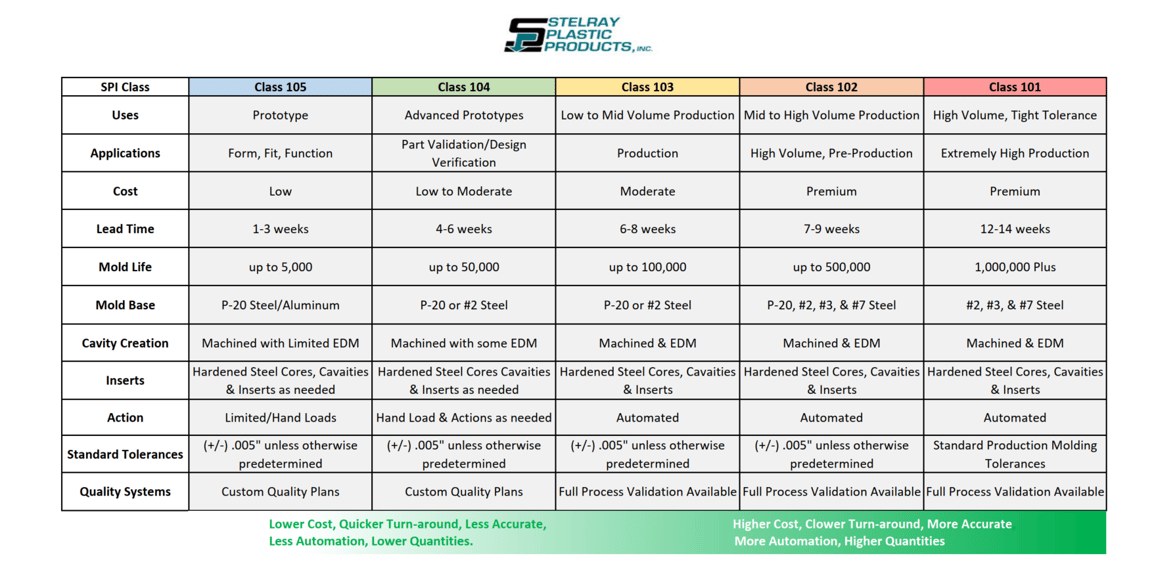

Our website's reference table page is a comprehensive resource for essential information on plastic materials and injection molding. It provides data on plastic density and shrinkage values, aiding users in understanding material characteristics during the molding process. The page also includes common plastic abbreviations for effective communication within the industry. Additionally, it offers insights into plastic draft angles, guiding designers in creating molds for efficient product ejection. Lastly, the reference table classifies injection molds based on complexity and application, assisting manufacturers in choosing the most suitable mold for their production needs. Whether you're a designer, engineer, or manufacturer, our reference tables and mold material list is a valuable tool for navigating the intricacies of plastic manufacturing.