Stelray Adds 3D Printed Tooling Services

As part of Stelray's commitment to exploring new and creative methods to deliver cost-effective injection molding solutions, we are thrilled to announce the availability of 3D Printed Tooling services with our custom tooling packages.

Partnering with cutting-edge American toolmakers, Stelray is now offering 3D printed steel mold core and cavity blocks alongside our existing, traditionally-machined steel core and cavity blocks through our suite of custom injection mold tooling options. These cavity and core blocks are production-ready with hardness up to 44 HRC pre-heat treat and surface finishes as fine as SPI A1.

Why Choose 3D Printed Tooling?

While traditional core/cavity blocks are machined from solid steel and require numerous unique EDM, milling and grinding operations, 3D printed core/cavity blocks are generated in a matter of hours through a two-step operation to the designed specifications every time.

"For injection molding, it is a game-changer. And we are thrilled to offer it to our customers."

-- Matthew Cohn, Engineering Manager at Stelray

Utilizing software with automatic toolpath generation and sintering scaling, the 3D printer prints, dries and shapes the tool before sintering in an adjoined furnace. The flowable metal paste combines powder metal, solvents and a binder to form the tool, delivering a low-waste, no-mess solution. When speed and scalability are at top-of-mind, 3D printed tooling is the optimal choice.

What Other Advantages Does 3D Printed Tooling Offer?

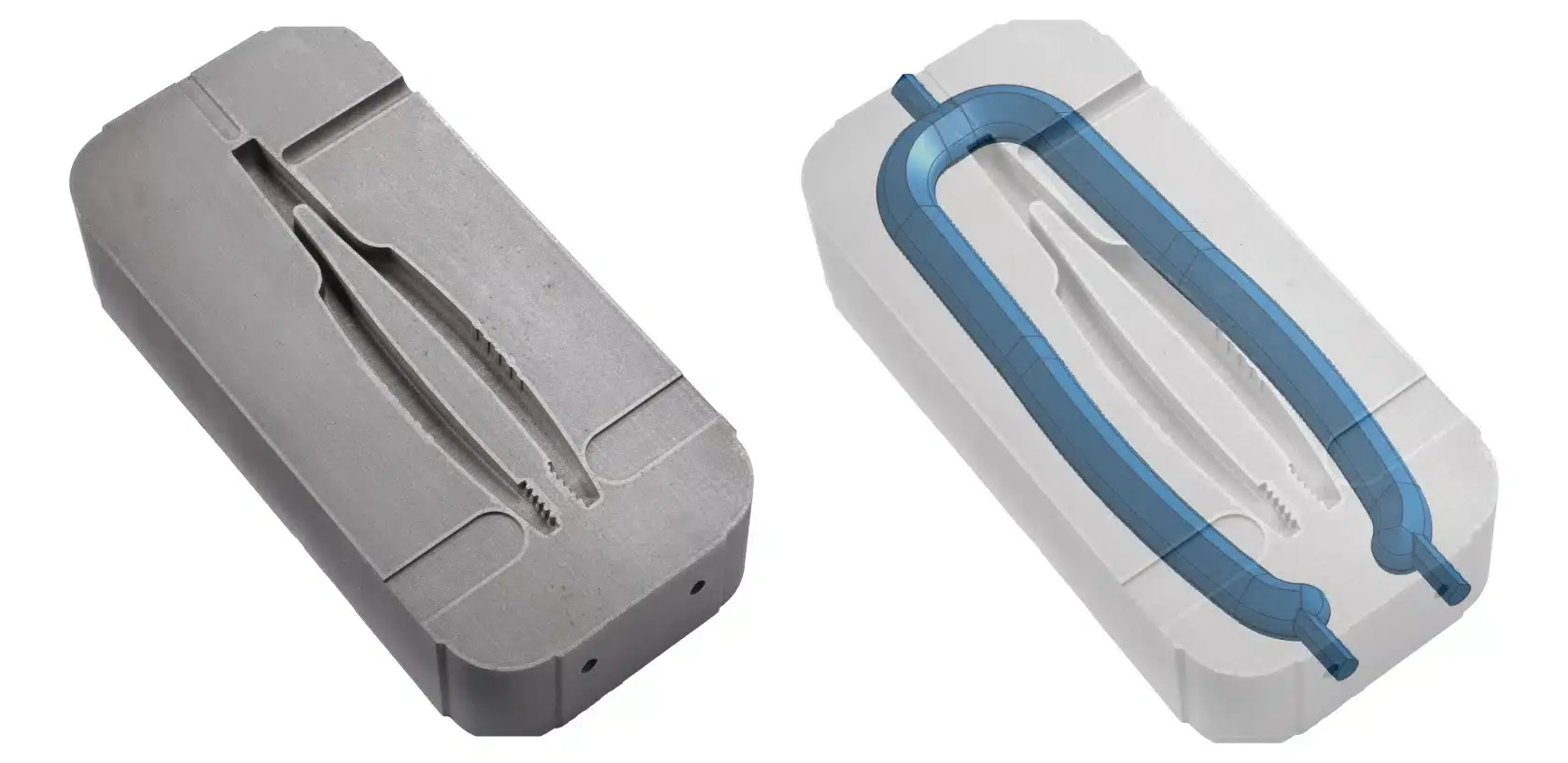

3D printing cavity blocks enables the implementation of conformal cooling networks not achievable with traditional cavity block design and manufacture. These cooling channels very closely follow the precise contours of the cavity to ensure uniform and even cooling during the molding cycle.

A highly-optimized cooling process achieved through conformal cooling will reduce molding cycle times while cutting down on defects like warping or sink marks—ultimately resulting in higher yield manufacturing. To learn more about resin characteristics during the molding process, check out our Reference Tables.

| 3D Printed cavity conformal cooling network. All images courtesy of Mantle 3D. |

Can 3D Printed Tooling Be Used for Production?

3D printed core/cavity blocks can often be associated with prototype-oriented molding solutions due to a short lead time and innovative profile but make no mistake: 3D printed core/cavity blocks are production-scale durable.

While Stelray is employing H13 Tool Steel material, 420 Stainless Steel will also soon be available for printing with additional materials being explored. Hardness ranges from 42 to 44 HRC post-sintering, guaranteeing each 3D printed tool can handle almost any job on the manufacturing floor. Should increased hardness be required, 3D printed core/cavity blocks can also be heat treated post-processing.

This is a breakthrough for Stelray's Engineering Manager, Matthew Cohn: "What has gotten us the most excited is that we are going to be able to address 90% of our molding scenarios with cavity stackups that take 10% of the time to manufacture. And, on top of that, we now have access to a method of part cooling that is going to raise the ceiling of production efficiency and quality. This is still a relatively new and developing technology, so we only expect better material selection to come—and soon. For injection molding, it is a game-changer. And we are thrilled to offer it to our customers."

How Can I Learn More?

Stelray remains deeply committed to navigating a rapidly-evolving American manufacturing economy with a focus on innovation and peerless customer service. If you are interested in learning more about how 3D printed tooling can fit into your custom injection molding program, please give us a call.