Benefits of Plastic Injection Molding

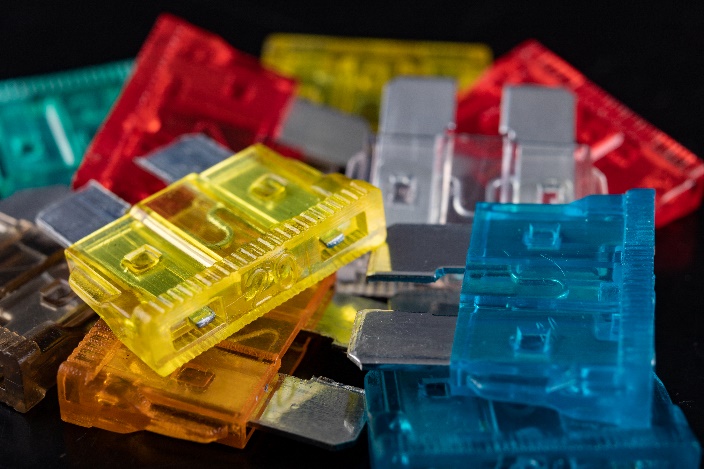

Plastic injection molding is used widely in the manufacture of everything from precision medical devices to children’s toys because of the many benefits it offers.

Plastic is one of the most versatile materials used in modern manufacturing, given it can be molded into a wide range of durable products—everything from high-precision medical devices to widely popular kids’ toys.

Injection molding offers numerous advantages over alternative manufacturing methods. Take a look.

High rates of production

Injection molding offers extremely fast cycle times—making it cost-effective for high-volume runs. Once a mold is complete, the process of molding molten plastic is quick, effective and highly scalable in output. The process also creates parts without the need for post-production refinement, a step involved with other manufacturing methods that costs time.

Precision quality parts

The process of injecting molten plastic into intricate molds under high pressure, creates complex, highly detailed designs with extremely tight tolerances of (+/-) .001”. This makes injection molding an ideal process for creating the types of high-precision parts and components required by the bioscience, automotive, electronics and aerospace industries.

Mold very small to very large parts

Plastic injection molding is highly versatile—offering the same quality and durability in everything from large-scale HVAC and plumbing units to micro components for high-precision applications like medical devices and wearable tech in which size and weight are primary factors.

Prototyping capabilities

Plastic injection molding for prototyping offers several unique advantages. Among them: It is a fast, efficient process that allows for designs to be in use early during product development, and the process is cost-effective enough to iterate multiple designs without causing budget-busting overruns. This type of tooling in the industry is considered as quick-turn mold or a bridge tool.

Customizable (color, texture, material)

Two classes of plastics are used in injection molding: thermoplastics and thermosets. Thermoplastics don’t undergo chemical change when heated, making them highly recyclable given they can be re-heated and re-molded repeatedly. Thermosets form irreversible chemical bonds during the curing process, making them less recyclable but more reliable in retaining strength and geometry even when exposed to high temperatures.

Both classifications offer multiple materials options for plastic injection molding manufacture—making them highly customizable to meet the demands of any project.

Cost-effective manufacturing with little waste

Plastic injection molding produces very little if any waste byproduct, making it more cost-effective than other manufacturing methods. Whatever waste is created generally can be recycled for future use, resulting in significant cost savings.

Improved mechanical/physical properties

Through the use of additives and by altering heating and curing processes, plastic injection molding can improve the mechanical properties of component parts to address such things as tensile strength and flexibility, warpage and dimensional stability, and temperature- and fatigue-resistance.

Ease of adding post-mold operations

Plastic injection molding is ideal for post-molding services when customers require more than just a molded part. Pad-printing, hot stamping, painting, plating and shielding services are available for decorating and coating requirements. In addition, ultrasonic welding and heat-staking resources are available to accommodate molded joining needs.

About Stelray

Stelray Plastic Products is a leading global plastic injection molding company providing cost-effective solutions across a wide range of applications and industries.

We have an outstanding supplier record of providing precision plastic molding, post-molding and prototyping services to an array of industries and Fortune 500 companies. We take pride in knowing that our customers rely on our team for consistent quality, superior service and on-time delivery.

Get in touch to learn more about our custom plastic injection molding services.