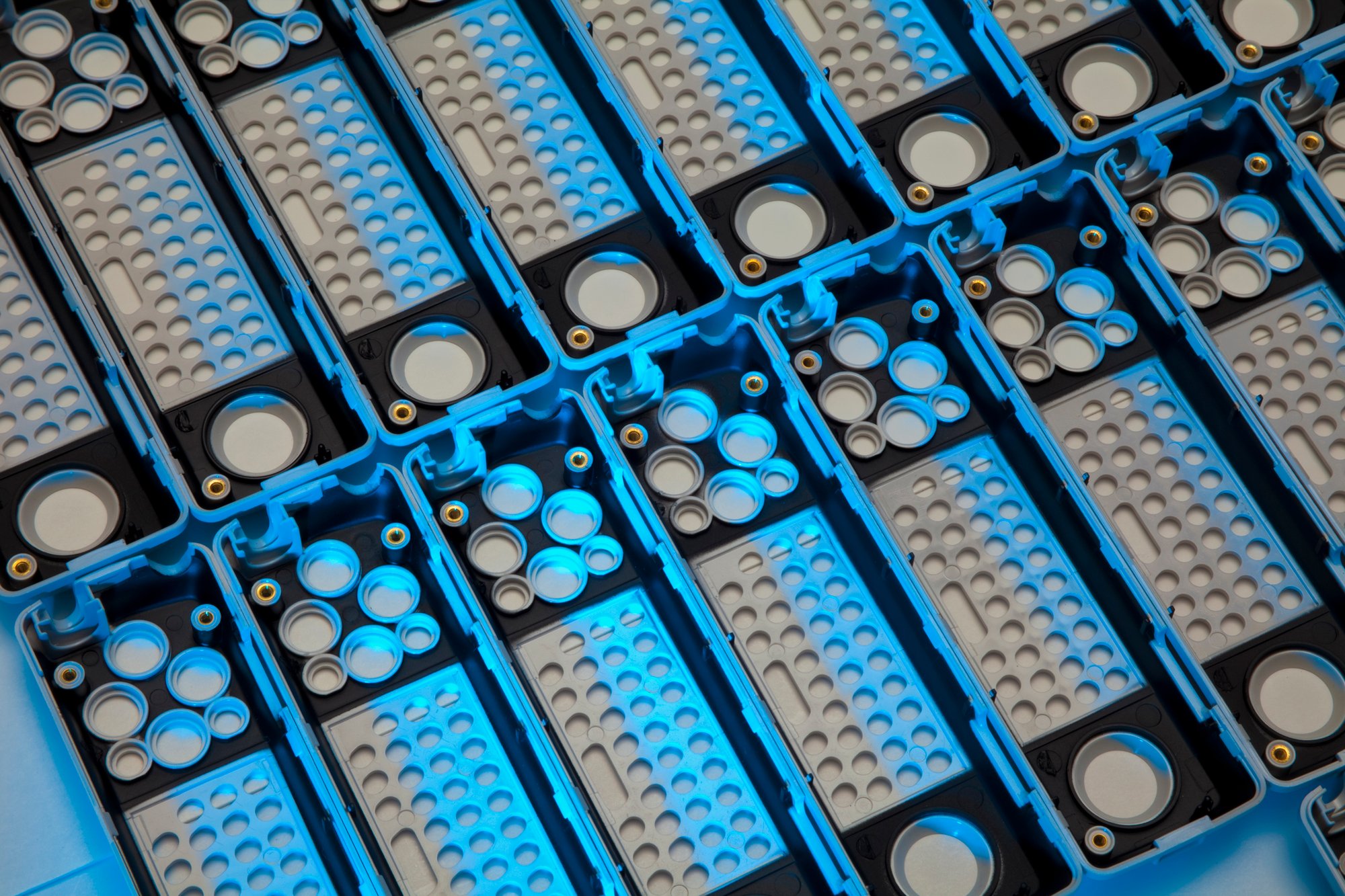

Engineering and 3D Prototypes

Experience innovation brought to life through our cutting-edge engineering and 3D prototyping solutions

Plastic Part Design and Engineering for Plastic Injection Molding

At Stelray Plastic Products, Inc., we are often asked to assist in the plastic part design development and prototyping of new product ideas for our customers. If “speed to market” is your concern, often times Stelray in-house 3D printing services can be the interim solution. As a full-service plastic injection molding company, we offer a number of product design, engineering services and material options to help develop, validate form, fit, and function of your part for successful plastic injection molding.

Whether you need two parts or 2,000,000 parts, Stelray can accommodate your plastic injection molding requirements. Allow us the opportunity to consult with you and we will recommend the best tooling and material options to meet your needs.

Check out our careers page to be a part of the Plastic Part Design and Engineering for Plastic Injection Molding team.

Engineering and Development Services

- Product Testing

- Material Testing and Validation

- Early stage engineering support

- Quality requirement planning

- Material Selection consultation

- Mold concept planning

Rapid prototyping

- 3D Printing – Leading edge “Additive Manufacturing” Quick way for your CAD model to become a physical part

- Injection Molded Prototypes

- Stereolithography (SLA)-functional 3D model for initial review of our design concept

- CU Models (Cast Urethane)

- CNC Machined and fabricated models – Best use if a 3D CAD model is not available and for fabricating a specific shape from a specific material

- Off-Shore Mold Building Alliances

- Low-cost injection molds

Plastic Part Design and Mold Tool Design

- Configuring part for consistent production

- Considerations in designing are reducing cycle time and minimizing defects

- Consideration for family molds to reduce part cost

- Assist with surface finish requirements

- Refine 2D or 3D CAD models

- Wire EDM technology

- Use of Mold-Tech texture or high speed polish SPI

Material Selection

- Choose resin and additives based on application

- Review thermal, mechanical and environmental properties

- Consultation for material reaction to fluids or solvents

- Consideration of cosmetic appearance

- Strength and flexibility of a material choice