Blood Storage System Injection Molding Sample Project

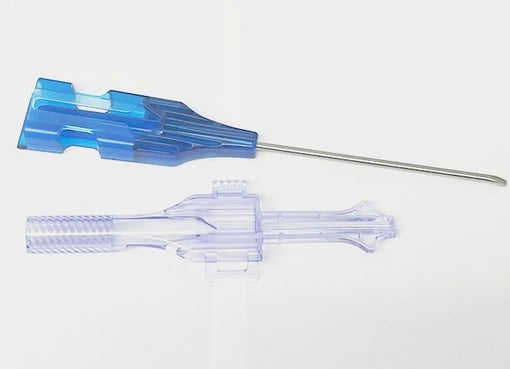

Stelray Plastic Products, Inc. was approached to design and build multiple injection molds and to produce parts to support a product launch for a new medical device being developed by a globally recognized healthcare products company. Working with the customers' project team, Stelray performed a DFM (Design for Manufacturability) to ensure the part was manufacturable and the design specifications were achieved. A detailed GANNT chart was provided for the project with bi-weekly meetings to review action items. To minimize capital expenditures to the customer, the molds were designed as family tools (1+1+1 and a 1+1), and handloads replaced machined cams where required. Material used for this medical product is a Lexan HSP1, to meet the Gamma sterilization requirements of the device.

The mold build and initial samples had a turnaround time of 8 weeks, after final mold design. A standard first article inspection was performed from the samples and approved by the client. To protect the parts during production and shipment, the parts are placed in a vacuum formed tray, designed, and supplied by Stelray. Our early supplier involvement of the program enables Stelray the ability to be instrumental toward a successful product launch and meet the timeline objective of the customer.

For more information on this project please download the project specifications or get in touch with us to find out how we can provide the perfect solution for your next injection molding application.

STELRAY PLASTIC PRODUCTS INJECTION MOLDING EXAMPLES

Stelray Plastic Products, Inc. provides quality plastic injection molded products to customers worldwide. As a full service plastic injection molding company, we offer in house mold tooling, design and engineering support and custom manufacturing for a variety of plastic injection molded products. Here are just a few plastic injection molding projects that we have provided our customers.

Blood Storage System Injection Molding Sample Project

A medical industry client required a stacked blood storage system that goes into a freezer where the blood-filled vials can be selected by a pick-and-place machine. Stelray managed the project, which included the mold and component manufacturing, sourcing, assembly and shipping. We also took on the tooling design and built the plastic injection mold as well as the assembly fixture. Stelray injection molded the plastic side pieces in addition to sourcing the die-cast pieces and hardware for the assemblies. The part is 5.5' high, 5.375' long and 3.875' wide. We used a top-fill polypropylene for the plastic parts and zinc for the die-cast parts and packaged everything in Gaylord boxes. Our turnaround time was 5 to 6 weeks and our full dimensional in-process quality testing and inspection inspectionensured that we met the customer-supplied and FDA specifications. For more information on this project please see below or get in touch with us to find out how we can provide your perfect solution.

ABS Power Tool Component Plastic Injection Sample Project

Stelray Plastic Products, Inc. helped design and manufacture the injection mold for a power tool hook and selected the best materials for the job’s requirements. We injection molded the 4.500″ long and 2.375″ wide part in ABS and co-polyester. We also sourced and procured the hardware and aluminum hook, riveted the clip to the housing and hot-stamped the part with yellow type. Before packaging the part for delivery to Texas, we ensured it met the customer-supplied specifications with a full in-process dimensional inspection.

It took us 6 to 8 weeks to develop, design and build the tooling, then an additional 3 to 4 weeks to do the high-volume production runs. Stelray Plastic Products is a one-stop shop that can handle everything from project management to design, procurement, prototyping, material specification, molding and more.

Plastic Injection Molded Component for Window Shade Assembly Sample Project

Stelray Plastic Products, Inc. produced this end housing that is used on a pin, in a power window shade assembly for a home interior industry client. We provided the plastic injection molding of the polycarbonate end housing and inserted the bronze bushing into the housing while the material was still expanded from the heat.

We knew that the interior diameter of the bushing was a critical dimension for quality control because it was the key to a proper fit. The part measured 4.5″ long with an outside diameter of 2.000″. It took us eight weeks to do the tooling and 2 to 3 weeks to produce each 1,000 unit run for delivery to Connecticut and California. To learn more about this plastic injection sample project, contact Stelray Plastic Products to discuss your particular requirements.

Are you ready to share your files? Fill out the form to upload them!

You'll speak with one of our engineers to discuss your plastic project.